TRICK's Shelf-Life simulation Add-on: A step forward against food waste

Food waste is a global crisis that affects not only our economy but also our environment and social welfare. One of the primary contributors to food waste is the shortening of the Shelf-Life of fresh foods. The loss of perishable items like fruits, vegetables, dairy, and meats represents a significant challenge in our efforts to combat food waste.

According to the Food and Agriculture Organization (FAO), approximately one-third of the food produced for human consumption is lost or wasted globally each year. This translates to a staggering 1.3 billion tons of food being discarded, worth nearly $680 billion. A significant share of food waste occurs even before food reaches the consumer. In fact, before the products reach the consumer, about 35% of waste occurs.

@Univerlab_FoodWaste

By integrating the Shelf-Life Simulation Add-on into the TRICK platform, it is possible to significantly reduce food waste while optimizing the profitability of the perishable food supply chain. This Add-on allows supply chain actors to monitor in real time the condition of the fresh products they operate with, including storage conditions like temperature and humidity and the residual Shelf-Life of each batch.

The shelf life, which will be expressed in days, is the estimated time in which the food products considered will deteriorate for various reasons. The main causes of deterioration are as follows:

- Development of bacterial and fungal populations

- Water leakage

- Oxidation and activation of enzymes naturally present in food

- Exposure to light radiation and heat sources

The calculation of the Shelf-Life is carried out independently by processing different data, which are automatically recorded by a hardware system or entered manually by the actors in the supply chain.

The data recorded by the hardware are the temperature and humidity at which the batch is stored and transported. The data entered by users are the type of product, the state of conservation at the time of production and the temperature estimate from the time of production to the activation of the hardware.

The hardware that has been developed and integrated into the Shelf-Life Simulation Add-on consists of a temperature and humidity measuring device, self-powered with a long-lasting battery, waterproof and able to store data and transmit them via RFID and NFC technology and an RFID control unit and antenna capable of consulting the sensors and transmitting data to the database.

In addition, the devices will be readable from any mobile phone with NFC technology, through a specially configured mobile app.The calculation of the Shelf-Life will be carried out using algorithms developed ad-hoc for this add-on, which allow obtaining accurate and reproducible data considering the mathematical functions that describe the deterioration of perishable foods.

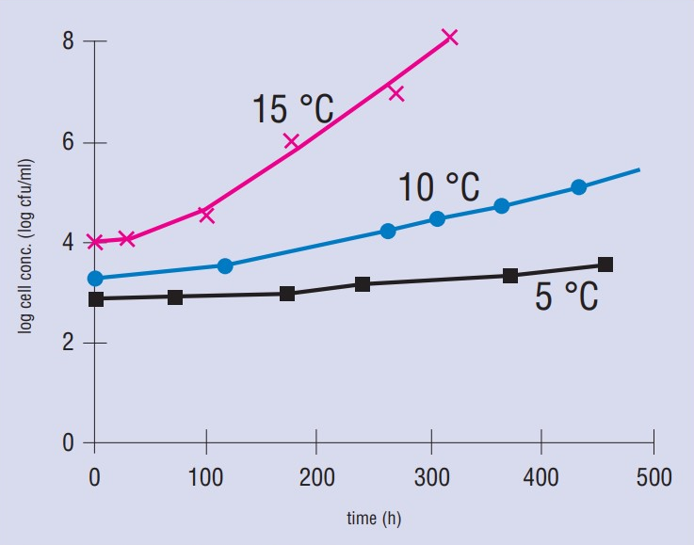

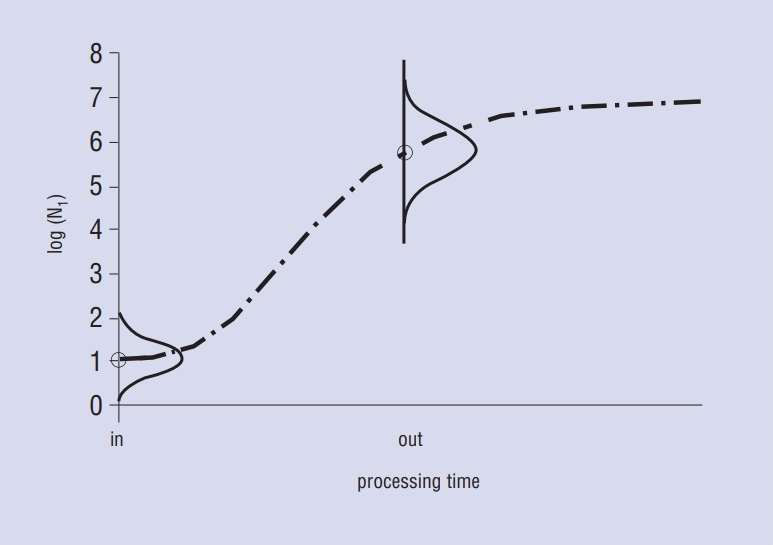

In the images below it is possible to see the isothermal curves of microbial growth in a perishable food (left) and the point value of microbial growth replaced by a probability function (right).

@Univerlab_Function1

@Univerlab_Function2

This add-on will be a fundamental support for food wholesalers of perishable foods, especially fruits and vegetables, who can decide the fate of several batches close to spoilage.

In fact, one of the tasks of wholesalers is to decide whether to send food to retail or to conversion companies, which transform fresh food into long-life by-products, such as juices, powders, additives, and flavorings. Obviously, the products that are destined for processing are sold at an almost halved price, but wholesalers often tend to prefer this option to prevent food close to decay from reaching stores.

Until now, these decisions, on which the value of the products sold largely depends, were taken mainly on an empirical basis, based on the experience of the operators and without any specific aid.

Thanks to the Shelf-Life Simulation Add-on it is now possible to rely on a powerful measurement and calculation tool that allows to optimize the profitability of each production batch, guaranteeing an informed choice regarding the fate of perishable foods during their distribution chain.

CONTACT PERSON & EMAIL ADDRESS:

-

Dr. Marco Valtolina (email)